To ensure the correct application and a long-lasting installation to a wooden sub-frame it should be compliant to the following requirements:

To ensure the correct application and a long-lasting installation to an aluminium sub-frame it should be compliant to the following requirements:

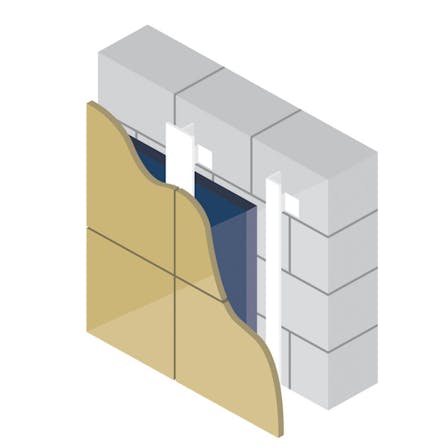

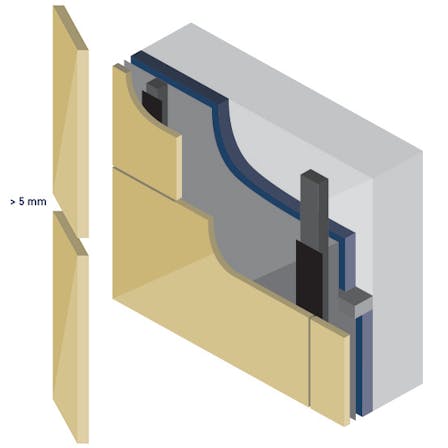

With an open construction, the horizontal joints should have a joint of a minimum 5mm. The vertical joints, with a minimum of 5mm are automatically closed by the backing of the vertical substructure. To ensure the durability of the wood, the vertical battens must be well protected against rain water. This can be done with a UV and weather-resistant EPDM foam tape that is 15mm wider on both sides than the framework. It can also be done with a strip of Rockpanel material, which acts as a gasket to protect the battens.

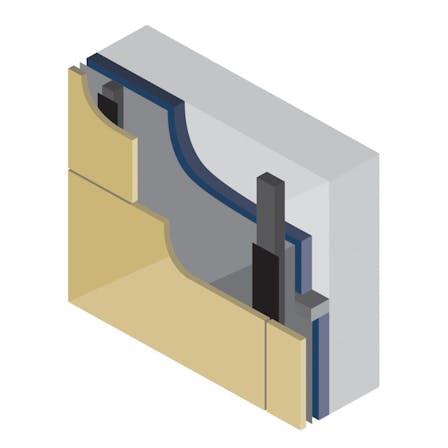

In a wooden construction, the structure behind the vertical batten should be protected with a breathable, water repellent and UV resistant membrane. The cavity between the Rockpanel boards and the membrane should be at least 28mm. When fixed with Rockpanel Tack-S on a Rockpanel strip the cavity should be at least 36mm (28mm thickness of batten plus 8mm of Rockpanel strip, according ETA). In a fire-safe construction with A2, fixed on an aluminium sub-frame, the cavity should be a minimum of 20mm. With an aluminium construction and open joints Rockpanel recommends a cavity depth of 40 - 100 mm. Application of corner cavity barriers is advised with open joints construction.

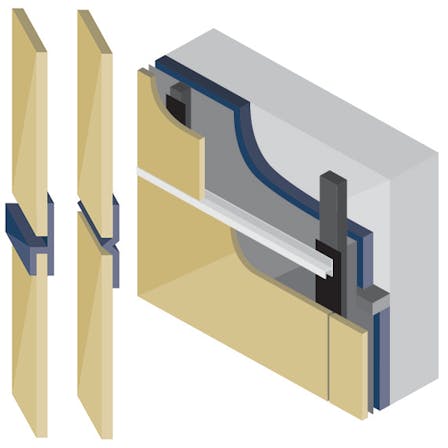

In a closed construction the horizontal joints are closed with a profile, usually a chair (Profile A) or nose profile (Profile B, semi-closed). This means that most of the rainwater is drained off from the outside of the exterior cladding. This structure still requires an air cavity of at least 28mm for timber sub-construction and at least 20 mm for metal sub-construction and a continuous opening of at least 5mm at the top and the bottom of the construction. The vertical joints are automatically closed by the backing of the vertical substructure. To ensure the durability of the wood, the vertical battens must be well protected against rain water. This can be done with a UV and weather-resistant EPDM foam tape. With a closed joint, the tape does not need to protrude. It can also be done with a Rockpanel strip.

Rockpanel boards are increasingly specified by architects and building managers who require a product which offers thermal, aesthetic and waterproofing benefits to ensure a healthy indoor climate in which people can live and work.

We manufacture board material mostly used in ventilated constructions, for facade cladding, roof detailing, soffits and fascias.