The benefits of using Rockpanel board material for creating your building facades, rooflines or guttering over more traditional building materials such as

wood, fibre cement board (FCB) and high pressure laminate (HPL) boards are clear:

The benefits of using Rockpanel board material for creating your building facades, rooflines or guttering over more traditional building materials such as

wood, fibre cement board (FCB) and high pressure laminate (HPL) boards are clear:

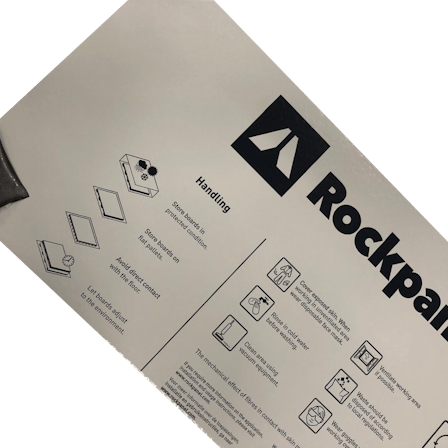

Most Rockpanel boards in our range are covered by a protective film, so they arrive with you in perfect condition. You can use the film to markup measurements and to aid the installation process.

When to remove the protective film:

01

02

03

04

We manufacture board material mostly used in ventilated constructions, for facade cladding, roof detailing, soffits and fascias.